From Idea to Reality

The search for like-minded and creative designers for our watch microbrand was far-reaching but rewarding. We were happy to have found young and promising talents in Li Mingliang and Liu Yuguan. With our founding duo and designers on board, the team behind Atelier Wen was complete.

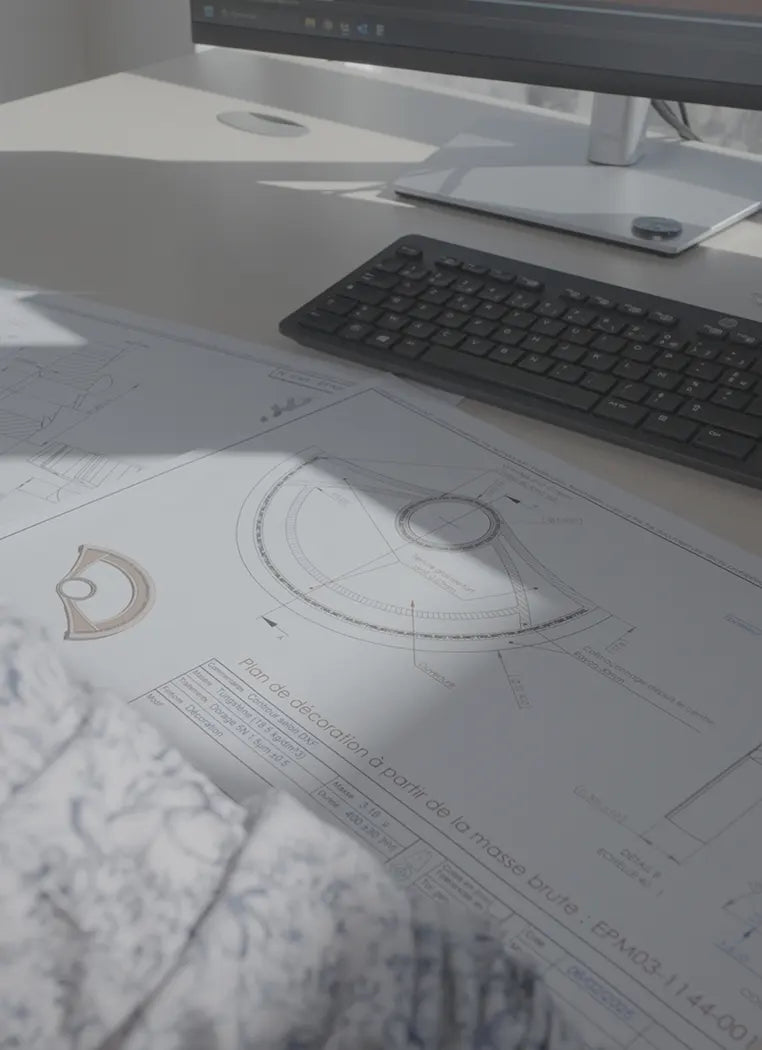

Even though our collaboration on the designs took some time as Robin and Wilfried were still balancing their time between graduate studies and the creation of the brand, the result proved rewarding. True to our vision of creating one of the very top Chinese watch brands, we knew we could not rush the process if we were to achieve what we aspired to. We spared no efforts and produced more than a hundred design iterations - and it was worth it.

After months of hard work, we unveiled our designs to the watch community, receiving great praise and the encouragement we needed to push the project to the next stage. Indeed, with the designs checked off our lengthy list, it was time to turn our attention to the next challenge - prototyping.

Creating the Prototypes

Oftentimes, microbrands rely on outsourcing the entire process of selecting suppliers and assembly to third parties. The upside is that it is faster, easier and more accessible to individuals new to the complexities of the industry. The downside is that one loses visibility over quality control and ends up paying a hefty markup, too often passed on to the end buyer. Faced with these two options and the desire to give the utmost attention to detail and provide a high quality watch at an affordable price point, we knew this would not work. We decided to strike out on our own and build our supply chain from scratch.

Wilfried on one of MANY supplier trips (pictured with an early prototype on his wrist!)

A watch’s movement is the most crucial component when creating a prototype. Fortunately, Robin’s extensive experience with the industry had already led him to visit most of the Chinese movement manufacturers (most notably from Seagull, Beijing, Shanghai, Dandong, and a few others). Out of all of these, he knew the calibers from Dandong Peacock to be the country’s absolute best. They were just what the proverbial doctor ordered.

In this way, we settled on working with Dandong Peacock early on. But as is always the case with fine horology, getting our movements to the standard we aimed for was painstaking work. Indeed, though the accuracy of the movement we decided on was good we felt that we would have to go one step further to really carve out a space for Atelier Wen amongst the best watch microbrands.

Seizing up a sample movement on a 3D-printed case

As a result, we went back to the manufacturer and convinced them to customise a movement exclusively for us to reach +/-10s/d accuracy and get rid of the crown’s “dead click” by removing the entire date mechanism. This was a long negotiation process and one that ultimately succeeded in no small part thanks to baijiu-imbibed visits up in freezing Dandong!

Our first visit to Dandong - our hosts take us out on a boat ride!

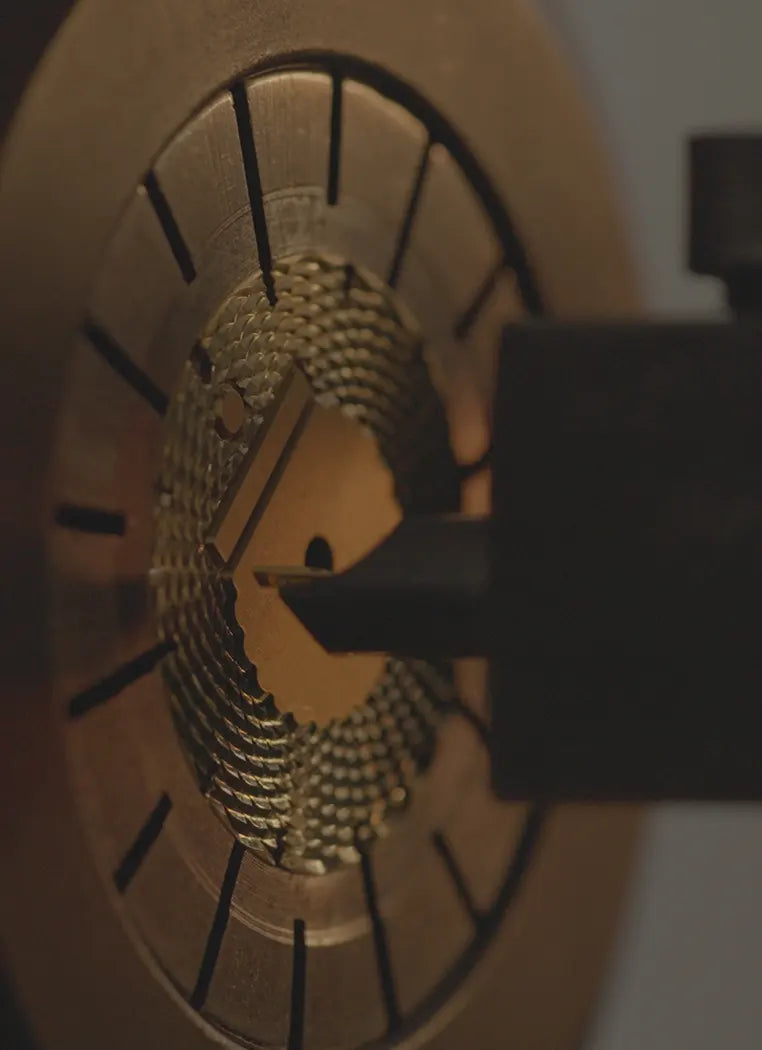

Next up were the heat-blued hands and porcelain dials - and these were particularly difficult to source. The only way to find suitable suppliers there was by way of referrals and we inevitably had to persuade these manufacturers to provide us these components given the high level of sophistication and unpredictable nature of these manufacturing processes. In the end, two of them relented and we were all set! But sure enough, our manufacturers’ concerns proved well-founded and for the blue porcelain dials, we ended up having to make more than 1000 units to get 250 up to the standard we wanted!

Our first finished dials

As for the other components, many iterations had to be completed each time before we achieved a result we were happy with. For instance, we made more than 10 differently-polished and brushed versions of the case and buckle alone!

One finely-made watch buckle

Truth be told, the prototyping process was longer and more arduous than we could have imagined. But, in the end, it was more than worth it. Though these were “just” prototypes, they turned out beautifully and were received with great reviews that really gave us hope for the next steps...

The end result...

Countdown till Launch

With the team yet another step closer to launching Atelier Wen, we were hard-pressed for time (quite the irony for our founding duo). It was around August 2018 when we finally received our prototypes and we had less than two months before our intended launch date.

As Robin met with watch journalists and bloggers in Europe, Wilfried was in Beijing shooting videos for the upcoming Kickstarter campaign. Meanwhile, we had loaned our prototypes to various collectors across the world to get further feedback. Things were suddenly getting very real… and it was exciting!

Next up, preparing for launch...